Proper sanitation of meat processing equipment eliminates pathogens like Salmonella and E. coli, which are responsible for 30% of foodborne illness outbreaks linked to contaminated surfaces. Thorough cleaning reduces microbial loads by up to 99.9% on stainless steel components, significantly improving food safety outcomes.

Residual proteins and fats left in equipment create ideal conditions for bacterial growth, doubling contamination risks within 4–6 hours. Biofilm formation–a resilient microbial layer resistant to standard cleaning–occurs in 67% of poorly maintained grinders and slicers, increasing the likelihood of cross-contamination between batches.

The USDA enforces daily cleaning under FSIS Directive 12.6.1, while EU Regulation (EC) No. 852/2004 requires documented sanitation cycles. Facilities that fail third-party audits due to poor equipment cleanliness face a 23% higher recall rate and average fines of $14,000 per violation, according to FDA data from 2023.

Start with a 140°F pre-rinse to remove debris and loosen fats. Apply a food-grade alkaline detergent using low-pressure sprayers, focusing on joints and hinges where biofilm accumulates. Finish with a 180°F flood rinse, a method shown to reduce bacterial loads by 99.8% in USDA trials.

Foam-based cleaners adhere well to vertical surfaces and crevices, providing 12–15 minutes of contact time to break down stubborn fatty deposits more effectively than liquid sprays. Use pH-neutral formulations to protect stainless steel from corrosion.

Ensure all chemical residues are removed during final rinsing–a step overlooked in 34% of FDA violation cases in 2022. Test surfaces with ATP swabs or pH strips to confirm compliance with SSOP requirements. Water below 120°F may leave soap films that attract contaminants, so maintain adequate temperature for effective rinsing.

Moisture promotes rapid bacterial regrowth; Listeria can double every 30 minutes on damp surfaces. Use compressed air nozzles for internal areas and microfiber cloths for external surfaces, ensuring airflow patterns prevent recontamination during drying.

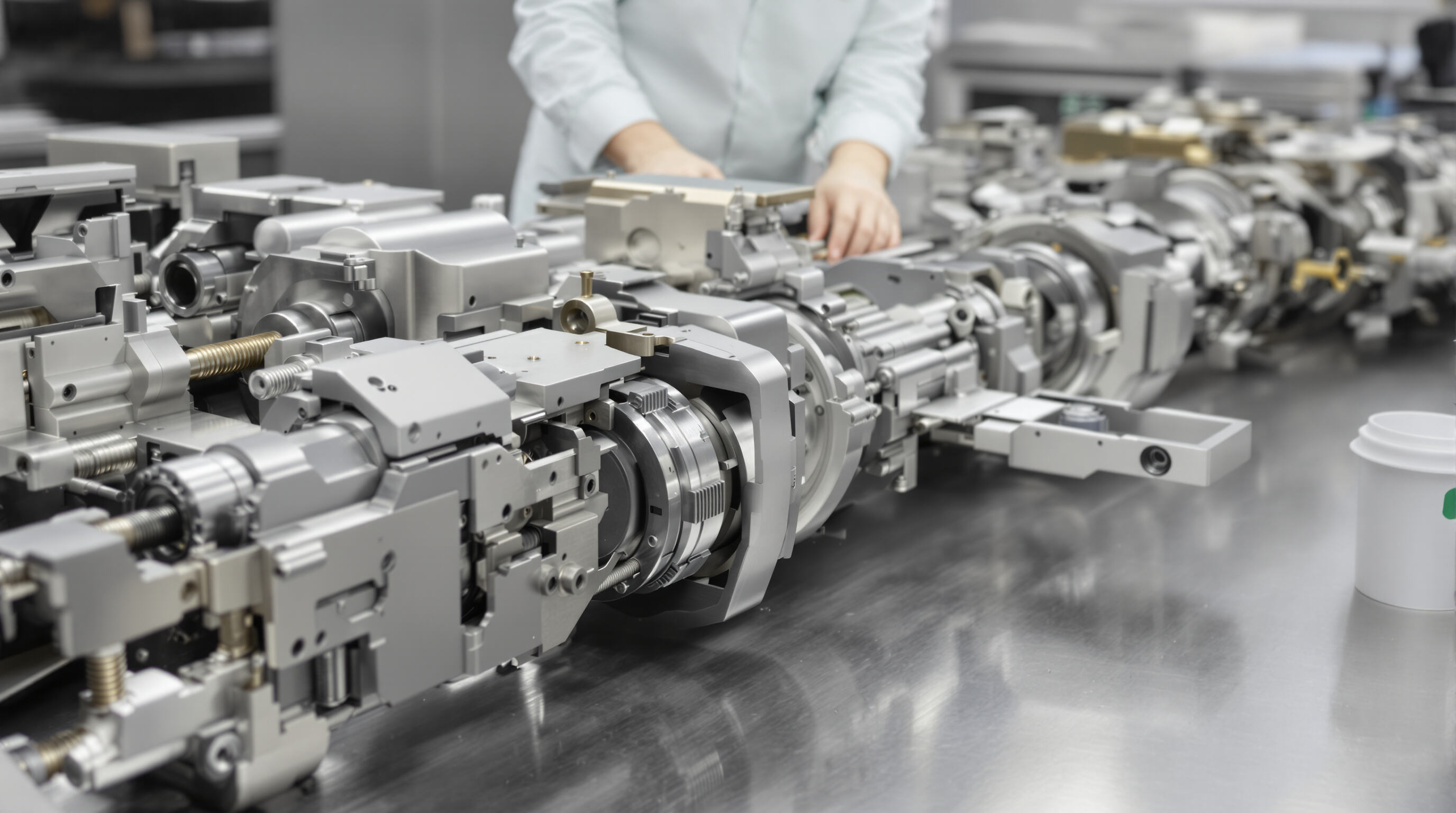

Complete disassembly is essential for effective deep cleaning. Inaccessible areas in assembled machines harbor 62% more biofilm than exposed surfaces. Remove augers, blades, and housing panels per manufacturer guidelines, especially those contacting raw meat. Automated systems enhance precision but require full power disengagement before maintenance.

Alkaline peroxides and chlorine-based compounds are most effective against Listeria biofilms. For rubber seals, use non-corrosive quaternary ammonium compounds (QACs) at 200–400 ppm. Emerging cold plasma technology has demonstrated 99.9% efficacy against Salmonella without chemical residues in recent trials.

Stainless steel withstands high-temperature sanitation (≥85°C/185°F for 15 minutes), while laser cleaning offers a non-abrasive alternative for sensitive electronics. Composite plastics require pH-neutral detergents below 50°C to avoid degradation. Always verify chemical compatibility using equipment manufacturers’ SDS documentation.

Accurate dilution prevents microbial adaptation–under-dosed solutions increase antibiotic-resistant bacteria risks by 34%. Use digital dispensers for consistency, apply foams or swabs to crevices first, then triple-rinse all surfaces with 60°C water, ensuring drainage points remain clear during reassembly.

Disassemble blade assemblies and clean meat particulates with nylon brushes to avoid metal scoring. Soak auger channels in 140°F (60°C) alkaline detergent, scrubbing spiral grooves where Listeria monocytogenes commonly persists. Pressure-rinse housing interiors at 25–30 psi, targeting hinge points and discharge chutes. Reassemble components while wet to minimize friction-induced corrosion.

Foam sanitizer should be applied to paddles and under lids since these spots tend to hold about 37% more organic material compared to vertical areas. Weekly maintenance with steam vacuum systems is essential for gears and bearings as they collect emulsified fat over time. When dealing with planetary grinders, locking the rotation mechanism during cleaning allows better access to those tricky cavity gaps. Pathogens actually stick around here for almost five times longer than they do on regular flat surfaces, making thorough cleaning absolutely critical for food safety protocols across commercial kitchens.

Soak band saw blades in ultrasonic tanks with peroxide-based solutions for 15 minutes to extract bone fragments from narrow teeth gaps. Lubricate guide rails weekly with NSF H1-approved grease. For tenderizer needles, follow a two-stage protocol:

Inspect blade edges with 10x magnifiers for micro-fractures that trap contaminants. Check auger alignment using laser levels–misalignment contributes to 28% faster biofilm recurrence. Document inspections digitally via SSOP checklists and retain records for 90 days as required by FDA CFR Title 21.

Documented SSOPs reduce contamination risks by 68% compared to informal cleaning practices. They should specify cleaning frequencies, chemical concentrations, and inspection checkpoints for grinders, slicers, and tenderizers. Facilities using digital SSOP tracking report 41% fewer FDA violations due to improved oversight and real-time logging.

The Hazard Analysis Critical Control Point system transforms regular cleaning routines into focused risk management strategies. Take for instance the disassembly of augers following pork processing operations. This step becomes a crucial control point where food safety teams can stop Listeria bacteria from taking hold in hard-to-reach areas. According to recent USDA findings, facilities that integrate their HACCP protocols with standard equipment maintenance schedules tend to address potential hazards approximately 53 percent quicker than those that don't. When it comes to verifying sanitation effectiveness, many plants now use ATP testing on band saws after thermal sanitization processes. While this approach satisfies basic HACCP verification standards, experienced plant managers know firsthand that consistent application remains the real challenge in maintaining these high standards across all production lines.

EU Regulation 852/2004 mandates traceable sanitization records for all surfaces contacting bovine or poultry products. Exporters must demonstrate minimum 82°C thermal sanitization cycles for mixer-grinders–14°C above baseline FSIS standards. Increasingly, third-party audits require spectral analysis of stainless steel to verify biofilm removal, reflecting rising global hygiene expectations.

Daily cleaning prevents the growth of harmful bacteria and reduces the risk of cross-contamination, ensuring food safety.

Biofilm is a resilient layer of microbes that forms on surfaces, making it difficult to clean and increasing contamination risks.

Sanitation Standard Operating Procedures (SSOPs) document daily cleaning practices to reduce contamination risks.

HACCP identifies critical control points in cleaning routines to reduce hazards and ensure food safety compliance.

Alkaline peroxides and chlorine-based compounds are effective against biofilm, while safe alternates like cold plasma are emerging.

Copyright © 2024 Zhaoqing Tengsheng Machinery Co., Ltd all rights reserved - Privacy policy