All conveyors, slicers, and sorting tables must undergo preoperational sanitation using alkaline-based cleaners to break down protein residues. Bacterial colonization on improperly cleaned stainless steel surfaces can reach 1,200 CFU/cm² within four hours of production downtime, significantly increasing contamination risks.

Implement a four-phase protocol:

This structured approach ensures thorough removal of biofilms and pathogens, aligning with FDA-recommended practices for high-moisture environments.

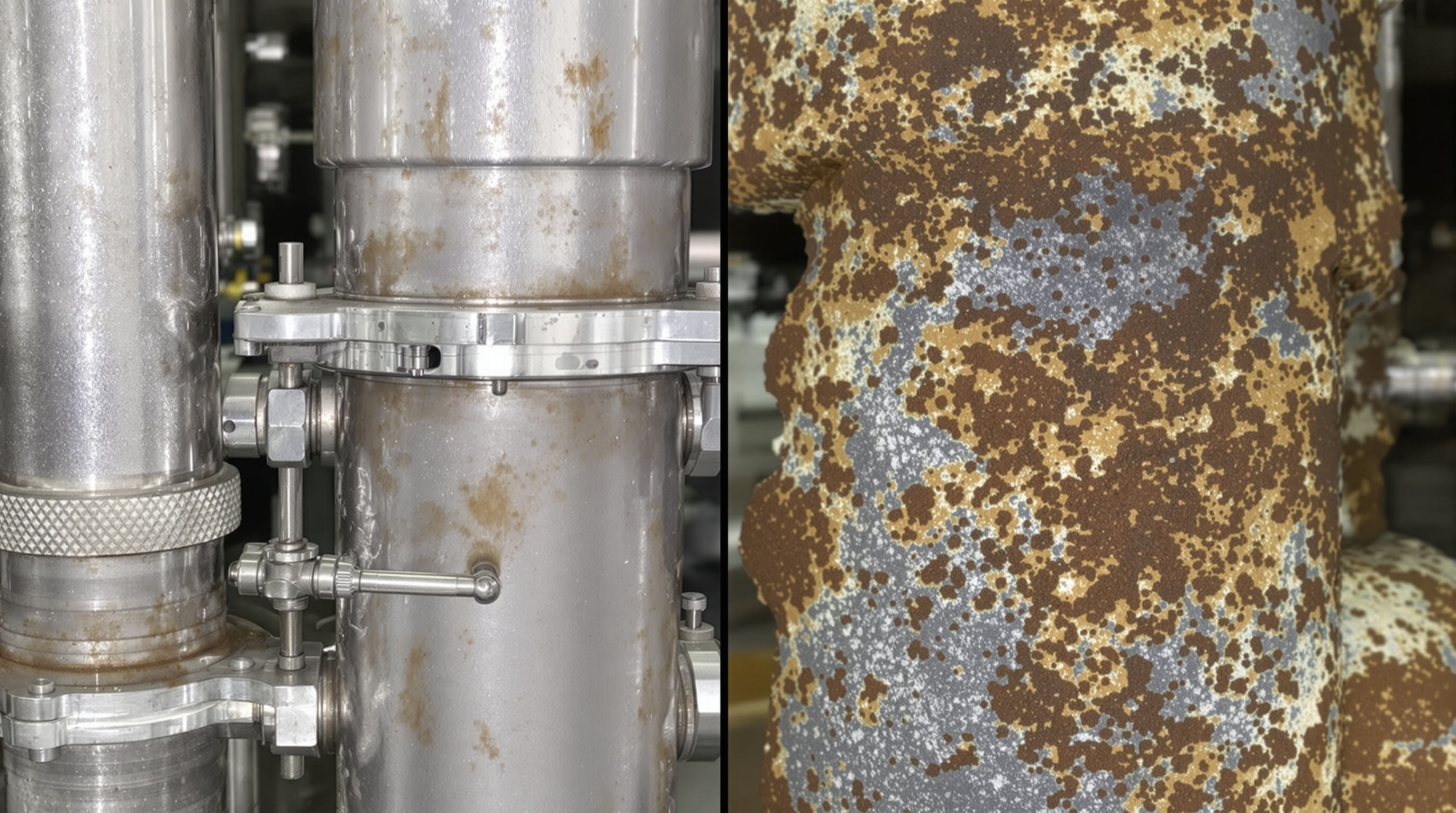

Quaternary ammonium compounds (quats) and peracetic acid blends are widely used due to their effectiveness against Vibrio species at low concentrations (0.2–0.5%). Facilities using non-compliant acidic cleaners report 37% higher corrosion rates on processing equipment, compromising both safety and longevity.

At a seafood processing plant along the Gulf Coast, managers tackled persistent Listeria issues by completely overhauling their operations. They introduced separate color-coded utensils for handling raw versus cooked products, installed ATP testing equipment that gives instant feedback on surface cleanliness, and set up mandatory hygiene stations complete with boot scrubbers at key entry points. The results were impressive: pathogen levels dropped dramatically, down around 90% within just under two years. Plus, production speeds actually went up about 15% during this period. So not only did they solve their food safety problems, but they also managed to boost overall efficiency without compromising on quality standards.

Standardized cleaning protocols reduce biofilm risks by 72% in high-moisture environments (EHEDG, 2016). Begin with a cold-water pre-rinse (¡40°F/4°C) to prevent protein denaturation, followed by a 160°F (71°C) alkaline detergent cycle. Focus mechanical scrubbing on welded seams and valves, where residues accumulate 34% faster than on smooth surfaces.

Automated CIP systems cut manual cleaning time by 40% while maintaining precise temperatures (165–185°F/74–85°C) and flow rates (¥5 ft/s) to eliminate pathogens in pipelines and tanks. Facilities using CIP achieve 99.9% coliform reduction compared to manual methods, ensuring consistent hygiene across closed-loop systems.

Material selection directly impacts the longevity of aquatic product processing equipment. Stainless steel is the gold standard due to its non-porous surface, which resists bacterial infiltration and corrosion. Facilities using 300-series stainless steel reported 34% fewer equipment replacements over five years compared to carbon steel alternatives (Material Durability Study, 2024).

Grade 316 stainless steel outperforms 304 in marine settings due to its 2–3% molybdenum content, which enhances resistance to chlorides and saltwater pitting. Grade 304 remains a cost-effective option for equipment exposed to freshwater or intermittent saltwater contact.

Porous surfaces like wood or low-grade plastics trap organic matter, creating breeding grounds for Listeria and Salmonella. A 2023 aquaculture safety report found that facilities using non-porous materials reduced biofilm-related contamination risks by 81%.

Good drainage starts with materials that won't soak up moisture or bacteria growth, so stainless steel grades 304 and 316 are commonly used because they stand up well against saltwater exposure and stubborn organic residue buildup. Most modern facilities install floors with a slope between 1% and 2%, plus position trench drains where water tends to collect naturally. The corners need rounding too since sharp angles just become little pockets for biofilms to form over time. According to research published last year, places that implemented all these features saw about a two thirds drop in detected pathogens when compared with older buildings that had flat floors and lots of crevices where contaminants could hide.

When water stands in processing areas, bacteria can multiply up to eight times faster just 30 minutes after it starts collecting. To prevent this problem, facilities should check drain covers every hour while running operations. Installing grated channels helps control scale buildup and keeps debris from clogging things up. And don't forget those backup alarm systems that go off when drains get blocked. According to a study by Ponemon back in 2022, companies lost around $740k because of contaminated products from drainage issues. That kind of money loss really highlights why having systems that monitor drains continuously makes such good business sense.

Establishing structured inspection cycles is critical for maintaining hygiene and functionality. A tiered checklist should include:

These protocols support HACCP compliance and prevent degradation before it impacts safety.

High-moisture environments accelerate corrosion, with even minor pitting on stainless steel creating niches for biofilm formation. Operators should inspect seals and gaskets for cracks, welded joints for discoloration, and belt surfaces for fraying. Early detection extends equipment lifespan by 20–40% compared to reactive repair strategies.

Sanitation is crucial to prevent cross-contamination, maintain hygiene, minimize bacterial colonization, and ensure safe food handling practices.

Follow a four-phase protocol: post-shift rinsing, foam application, mechanical scrubbing, and a final sanitizer rinse.

Non-porous materials like stainless steel, particularly grades 304 and 316, are recommended for their resistance to corrosion and bacterial infiltration.

FDA-compliant sanitizers such as quaternary ammonium compounds and peracetic acid blends are effective against various species and ensure safety and longevity of equipment.

Copyright © 2024 Zhaoqing Tengsheng Machinery Co., Ltd all rights reserved - Privacy policy